Use a drill press to ensure that the holes are drilled vertically. You have to evaluate the value youre getting from your square tubing roller dies before considering it. I recommend practicing plunge cuts on some scrap plywood first if you have never done them before. For that reason, we have gathered a list of the top square tubing roller dies products on the market, for your convenience. Thanks! By utilizing industry-standard criteria, we assessed them using our artificial intelligence to find the top square tubing roller dies on the market! Does the manufacturer no longer support supposedly good products like square tubing roller dies? Our YP-38 compact metal bender provides an economical way to achieve many of the most needed bends. You wont be held responsible for things that have gone wrong with previous customers, will you? Now on to making die sets Before you can start bending tubing, you'll need to make a set of 3 dies for each type of tubing that you want to bend.  Therefore I will tell you, for example, "use a right hand turning tool" or "cut .020" at a time," but I will not tell you what a right hand turning tool is, or how to read, zero out, or use the dials to make a .020" cut. Yes, I will be buying or making one of those soon. They are actually one of the easier die sets to make, as they don't require cutting a curve like the round tubing dies do. All these are made of reinforced steel for durable use. Balusters, Cast Iron & Steel Deco Components, Skip to the beginning of the images gallery, Copyright Jansen Supply Co. All rights reserved 2020, Bends square tubing up to 2 x 2 x 11 ga., rectangular up to 1 x 2 The Hard Way.

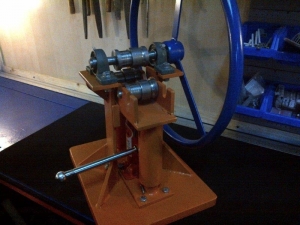

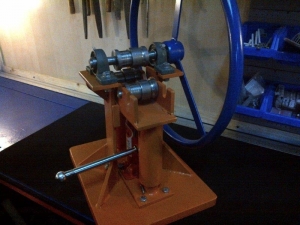

Therefore I will tell you, for example, "use a right hand turning tool" or "cut .020" at a time," but I will not tell you what a right hand turning tool is, or how to read, zero out, or use the dials to make a .020" cut. Yes, I will be buying or making one of those soon. They are actually one of the easier die sets to make, as they don't require cutting a curve like the round tubing dies do. All these are made of reinforced steel for durable use. Balusters, Cast Iron & Steel Deco Components, Skip to the beginning of the images gallery, Copyright Jansen Supply Co. All rights reserved 2020, Bends square tubing up to 2 x 2 x 11 ga., rectangular up to 1 x 2 The Hard Way.  Something went wrong. Our company aims for products which provide greater value than the standard, but with a good balance between square tubing roller dies. Now we need to cut out holes in the side pieces to reduce the weight of the machine (and because it looks cool). However, to get you started, I will walk you through how to make a 1 1/2" round tubing die. I use Draft Sight a free easy to use 2D drafting software that is compatible with AutoCAD. In order to eliminate confusion, I have both taken pictures and made technical drawings of the various parts, when the technical drawings and pictures conflict, the dimensions and locations on the drawings always override those in the pictures. Reply Submit Your Inquiry Tube Pipe Rolling Bender and Tube Die Set, Compact and Powerful Internal On/Off Switch N0 Electricity Required! Then, flip it over and add 2 bearings, one on each side, in the location of your choice. Universal Usage: A multifunctional steel bender machine produces grids, gates, balcony railing, patio furniture, iron lamps, power construction, road building, bridges pipeline laying or repairing, etc. Tmall Taobao World If youre looking for a company that can provide quality support. Simply insert the end of the tubing between the dies and start cranking the turning handle. Lets continue! Now cut out pieces for the center slide. I was hoping their might be a set of dies you could make for something like this to do it, but my googling hasn't resulted in anything detailed enough. Measuring units, Measures in feet and inches. Now cut two 9" pieces and one 18" piece of 3/4" shaft, then slide the 9" pieces in place between the side bearings and the 18" piece into the center slide. | Suppliers In this instructable, I will be showing you how to build a roller-bender machine from scratch.

Something went wrong. Our company aims for products which provide greater value than the standard, but with a good balance between square tubing roller dies. Now we need to cut out holes in the side pieces to reduce the weight of the machine (and because it looks cool). However, to get you started, I will walk you through how to make a 1 1/2" round tubing die. I use Draft Sight a free easy to use 2D drafting software that is compatible with AutoCAD. In order to eliminate confusion, I have both taken pictures and made technical drawings of the various parts, when the technical drawings and pictures conflict, the dimensions and locations on the drawings always override those in the pictures. Reply Submit Your Inquiry Tube Pipe Rolling Bender and Tube Die Set, Compact and Powerful Internal On/Off Switch N0 Electricity Required! Then, flip it over and add 2 bearings, one on each side, in the location of your choice. Universal Usage: A multifunctional steel bender machine produces grids, gates, balcony railing, patio furniture, iron lamps, power construction, road building, bridges pipeline laying or repairing, etc. Tmall Taobao World If youre looking for a company that can provide quality support. Simply insert the end of the tubing between the dies and start cranking the turning handle. Lets continue! Now cut out pieces for the center slide. I was hoping their might be a set of dies you could make for something like this to do it, but my googling hasn't resulted in anything detailed enough. Measuring units, Measures in feet and inches. Now cut two 9" pieces and one 18" piece of 3/4" shaft, then slide the 9" pieces in place between the side bearings and the 18" piece into the center slide. | Suppliers In this instructable, I will be showing you how to build a roller-bender machine from scratch.  Once you put together whatever crank you're using, slide it into the bearings in the center slide, and you'll have finished the body of the roller-bender. For the crank, I decided to re-use the crank wheel from the harbor freight tubing roller. 33 stand supports the large baseplate, which allows for a stable bending process. Oversized, and it won't fit; undersized, and it won't work properly. 7075 is harder than 6061 but unless hard anodized will still be pretty softI would think they will wear very quickly and have a series of flats if used with steel tube?

Once you put together whatever crank you're using, slide it into the bearings in the center slide, and you'll have finished the body of the roller-bender. For the crank, I decided to re-use the crank wheel from the harbor freight tubing roller. 33 stand supports the large baseplate, which allows for a stable bending process. Oversized, and it won't fit; undersized, and it won't work properly. 7075 is harder than 6061 but unless hard anodized will still be pretty softI would think they will wear very quickly and have a series of flats if used with steel tube?

- Adjustable lock collars to keep material aligned. Tap the holes in the large thick piece with a 3/8-16 tap, and assemble the top piece as shown in the last 3 images. Drill two 5/16" holes 1" deep in both ends of each piece, and thread them with a 3/8-16tap. Adopts a precise gear structure design with an accuracy of0.5%. Now use 4 pieces of 1" by 1/4" by 1" aluminum bar stock to make tracks for the center slide to slide in. Your reasonable suggestions will be taken into consideration as we make corrections to our list. Our top rated square tubing roller dies list excludes products that received mostly negative reviews. Also, it is important to make sure that both side pieces are as close to identical as possible, otherwise it will create problems later. Be sure to wear a face shield and gloves when cutting the aluminum, as the chips tend to fly everywhere and can be quite sharp. Terms of Use You get what you pay for, according to an old saying. on Step 33. | Showroom Then, if you haven't already, add the tracks for the center slide. High Flexibility: With adjustable roller for flexibility and easy operation.

- Adjustable lock collars to keep material aligned. Tap the holes in the large thick piece with a 3/8-16 tap, and assemble the top piece as shown in the last 3 images. Drill two 5/16" holes 1" deep in both ends of each piece, and thread them with a 3/8-16tap. Adopts a precise gear structure design with an accuracy of0.5%. Now use 4 pieces of 1" by 1/4" by 1" aluminum bar stock to make tracks for the center slide to slide in. Your reasonable suggestions will be taken into consideration as we make corrections to our list. Our top rated square tubing roller dies list excludes products that received mostly negative reviews. Also, it is important to make sure that both side pieces are as close to identical as possible, otherwise it will create problems later. Be sure to wear a face shield and gloves when cutting the aluminum, as the chips tend to fly everywhere and can be quite sharp. Terms of Use You get what you pay for, according to an old saying. on Step 33. | Showroom Then, if you haven't already, add the tracks for the center slide. High Flexibility: With adjustable roller for flexibility and easy operation.  This will allow the bolts to pull the pieces more tightly together. As part of our goal to provide the best experience to our readers, we have added a final layer of filtering. Conch-House.comis a participant in the Amazon Associate program and will earn from qualifying purchases. First, use 7/16" bolts to mount the bearings to the side plates as shown in the first 3 images, then mount the side plates to the top plate. It is only through thorough research that one can come across the best products. Very slowly, tilt the saw down and back until the blade makes contact with the workpiece, and continue slowly lowering the blade until it cuts all the way through the workpiece. Use a 1/4-20 tap to thread the holes, and screw 1/4" by 1"bolts and nuts into the holes. If you build just the roller, you can easily do it for around $300-400. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. Now that you have a temporary handle for your roller, you can roll your own crank wheel for a more elegant-looking one, or just leave it the way it is. ), 6 - flange block bearing (I used UCF204-12), Various nuts, bolts, lock washers, and washers, sizes 1/4", 3/8", and 7/16", Lathe tooling for boring, facing, drilling, and other standard operations, Drill press or Vertical milling machine with tooling for drilling, Precision calipers (accurate to .001" is fine), Basic knowledge of how to use a lathe without killing yourself. Also, if you disregard my warnings and stupidly attempt to do this project even though you don't know what you're doing, I am not responsible for you cutting off fingers or killing yourself as a result. It takes practice, but just go slowly and don't cut too deep; you should be fine. The metal bender is well-built and lightweight; you can mount it on work trucks, tractors, or concrete floors. Well Constructed: Adopts triangular base and thickened screw rod for ease of use & stability during bending process. your better off bending then 'barrel' plating a batchChrome plating will probably flake off on inside of bend and crack on outside radius Chrome doesn't like being compressed or stretched, Tip

This will allow the bolts to pull the pieces more tightly together. As part of our goal to provide the best experience to our readers, we have added a final layer of filtering. Conch-House.comis a participant in the Amazon Associate program and will earn from qualifying purchases. First, use 7/16" bolts to mount the bearings to the side plates as shown in the first 3 images, then mount the side plates to the top plate. It is only through thorough research that one can come across the best products. Very slowly, tilt the saw down and back until the blade makes contact with the workpiece, and continue slowly lowering the blade until it cuts all the way through the workpiece. Use a 1/4-20 tap to thread the holes, and screw 1/4" by 1"bolts and nuts into the holes. If you build just the roller, you can easily do it for around $300-400. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. Now that you have a temporary handle for your roller, you can roll your own crank wheel for a more elegant-looking one, or just leave it the way it is. ), 6 - flange block bearing (I used UCF204-12), Various nuts, bolts, lock washers, and washers, sizes 1/4", 3/8", and 7/16", Lathe tooling for boring, facing, drilling, and other standard operations, Drill press or Vertical milling machine with tooling for drilling, Precision calipers (accurate to .001" is fine), Basic knowledge of how to use a lathe without killing yourself. Also, if you disregard my warnings and stupidly attempt to do this project even though you don't know what you're doing, I am not responsible for you cutting off fingers or killing yourself as a result. It takes practice, but just go slowly and don't cut too deep; you should be fine. The metal bender is well-built and lightweight; you can mount it on work trucks, tractors, or concrete floors. Well Constructed: Adopts triangular base and thickened screw rod for ease of use & stability during bending process. your better off bending then 'barrel' plating a batchChrome plating will probably flake off on inside of bend and crack on outside radius Chrome doesn't like being compressed or stretched, Tip  The dies were actually the best part of the HF roller, I am temporarily reusing some of them until I get around to making full sets. Now it's time to drill holes so that we can bolt together the pieces of the center slide. Bending Angle Round Tube, Square Tube, Pipe Bending Machine Stainless Steel Carbon Steel Roller Pipe Bending Machine Mandrel Square Tube Rectangular Pipe Bender, Automatic Hydraulic Stainless Steel Ring Pipe Bending Machine Electric Single Head Hydraulic 3D Roller Square Tube Bender, Tube hydraulic steel pipe bender 1/2 roller bending machine moulds square parts electric manufacturer in china for tubes, High precisioncnc rebar coil bender machine stirrup Steel pipe profile bending forming spiral steel large pipe coiling machine, Rotary bender cnc tube pipe bender thin wall square tube tubing pipe roller bender, CA-129 Electric rolling pipe bender machine,tube bending machine three roller bending machine, 2021 New For Sale Moffler Craigslist Die For 6inch Cercll Tubing Roller Wg 76 Pipe Tube Bender, Heavy duty automatic gi conduit round square ss roller with mandril hydraulic air conditioner cnc tube pipe bender for sale, TR-60 TTMC Brand New Tube Rollers, Tube & Pipe Rollers, Radius Bender, hot sale competitive price 3 axis hydraulic 3 roller 360 degree cnc pipe profile bending machine, Hydraulic Tube Bending Machine HRBM65 HRBM65HV, metal pipe bending machine WG-51 pipe bender in china roller pipe bender, latest design electric tube bending machine for pipe and tube parts, Square Metal Pipe Tube Bending Machine Tube Bender, HW38/50/75 display rackes indicators Electric steel pipe tube bender manual bending machine, Square Tube Bender and Ring Roller Aluminum Arc Bending Machine for Sale, Section Bending Machine W24S Pipe Bender / Angle / Square Tube Bending Machine, High Power square tube Steel Pipes profile tube bender Hydraulic 3 Roll Pipe Bending Machine, JY-50 high quality sheet metal circular duct tube electric vertical angle roll bender, steel bar tube bender machines square pipe bending machine stainless steel pipe round pipe bender, Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Hook the springs on the 1/4" bolts. In order to ensure the best fit possible, use the center slide as a spacer to line up your tracks (theoretically, if your cuts were perfect, the outer edges of the tracks would line up with the triangular holes in the side plates, but my cuts were not perfect, and I doubt yours are either unless you used a CNC cutter). In addition, drill 2 holes in the center of each side piece, also 1" in diameter. Now, use right angle clamps to hold together 3 of the pieces as shown in the first image, and drill two 5/16" holes through each 1/2" thick piece and into the sides of the 1" thick piece. Then, again, for the (less than the) price if the 1/2" aluminum plate, there is HFT. If you are the kind of person who cuts corners and blatantly disregards their own safety, go somewhere else. Then, set the bottle jack on top of the center slide and add 4 springs, 2 on each side. We first gathered product information from reliable sources using the algorithms we had created. Among them are: Why would you purchase a cheap brand that is unable to meet your expectations? 2022 HOME | Conch House Marina | St. Augustine, FL Built with, Square Tubing Roller Dies,Compatible With, Top 10 Best Delta 50 345 3 Reviews In 2022, We currently have 67 different Die Sets in stock, Each die set is 100% CNC machined out of 1018 steel for a precise fit, Due to many operator controlled variables there is no warranty on our dies, IF ROLLING MATERIAL 1.5 AND LARGER; PLEASE SEE RECOMENDED UPGRADES IN THE DESCRIPTION BELOW, 1 Square Tube Roller for TR50,1-1/4 Square Tube Roller for TR50, 1-1/2 Square Tubing Roller for TR50, 1-3/4 Square Tube Roller for TR50. My roller features multiple locations to place the bottom dies, allowing you to place them farther apart for larger radii, which in turn requires less effort to do the rolling. Clamp the tracks in place, make sure the center slide can freely slide up and down the entire length of the tracks, and drill 4 equally spaced 3/8" holes in each one. 9999.11 Maximum Capacity U.S. There are 2 ways in which you can mate the drive die to the drive shaft, one of which is to cut an interior keyway and use a square key to mate with the shaft. Kaka Industrial TR-40 Tubing Rolling Bender Maximum capacity is up to 1-1/2 "x 14 gauge square tubes with multiple passes.For Mild Steel Cooper and Aluminum,Manual Square and Rectangular Tube Bender, Spare part for KAKA Industrial TR-40 Square and Rectangular Tube roll Bender, KAKA TR-60L Manual Tube Pipe Roller Bender, High Precision Tubing Pipe Bender WITHOUT Rollers. Specifically how are window well covers with angle iron bent symmetrically. No Power Outage Risk! B2-20120091-4. I recommend clamping it in place and drilling holes through both the top part and the side plates at the same time to ensure that the holes line up. The handle features a large for more comfort. Don't worry, your details are safe with us. You will enjoy faster opening times, better quality, and a better view by paying more for your product. Once you finish tapping all the bolt holes, test fit the 3 pieces of the center slide. I accidentally didn't drill the holes deep enough, and so I had to use several washers as spacers to let the bolts tighten up. And The metal bending tool is made of A3 high-hardness steel; it can be used for a long time. Our goal is to showcase products from a select few, if not more, trustworthy sellers. We would appreciate your input. Be sure not to twist the saw from side to side at all, or the blade can bind in the cut, mess things up, break teeth on the blade, throw the saw out of the cut, etc. I would make and use something like this: to turn my dies BUT it wouldn't be hand operated!!

The dies were actually the best part of the HF roller, I am temporarily reusing some of them until I get around to making full sets. Now it's time to drill holes so that we can bolt together the pieces of the center slide. Bending Angle Round Tube, Square Tube, Pipe Bending Machine Stainless Steel Carbon Steel Roller Pipe Bending Machine Mandrel Square Tube Rectangular Pipe Bender, Automatic Hydraulic Stainless Steel Ring Pipe Bending Machine Electric Single Head Hydraulic 3D Roller Square Tube Bender, Tube hydraulic steel pipe bender 1/2 roller bending machine moulds square parts electric manufacturer in china for tubes, High precisioncnc rebar coil bender machine stirrup Steel pipe profile bending forming spiral steel large pipe coiling machine, Rotary bender cnc tube pipe bender thin wall square tube tubing pipe roller bender, CA-129 Electric rolling pipe bender machine,tube bending machine three roller bending machine, 2021 New For Sale Moffler Craigslist Die For 6inch Cercll Tubing Roller Wg 76 Pipe Tube Bender, Heavy duty automatic gi conduit round square ss roller with mandril hydraulic air conditioner cnc tube pipe bender for sale, TR-60 TTMC Brand New Tube Rollers, Tube & Pipe Rollers, Radius Bender, hot sale competitive price 3 axis hydraulic 3 roller 360 degree cnc pipe profile bending machine, Hydraulic Tube Bending Machine HRBM65 HRBM65HV, metal pipe bending machine WG-51 pipe bender in china roller pipe bender, latest design electric tube bending machine for pipe and tube parts, Square Metal Pipe Tube Bending Machine Tube Bender, HW38/50/75 display rackes indicators Electric steel pipe tube bender manual bending machine, Square Tube Bender and Ring Roller Aluminum Arc Bending Machine for Sale, Section Bending Machine W24S Pipe Bender / Angle / Square Tube Bending Machine, High Power square tube Steel Pipes profile tube bender Hydraulic 3 Roll Pipe Bending Machine, JY-50 high quality sheet metal circular duct tube electric vertical angle roll bender, steel bar tube bender machines square pipe bending machine stainless steel pipe round pipe bender, Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Hook the springs on the 1/4" bolts. In order to ensure the best fit possible, use the center slide as a spacer to line up your tracks (theoretically, if your cuts were perfect, the outer edges of the tracks would line up with the triangular holes in the side plates, but my cuts were not perfect, and I doubt yours are either unless you used a CNC cutter). In addition, drill 2 holes in the center of each side piece, also 1" in diameter. Now, use right angle clamps to hold together 3 of the pieces as shown in the first image, and drill two 5/16" holes through each 1/2" thick piece and into the sides of the 1" thick piece. Then, again, for the (less than the) price if the 1/2" aluminum plate, there is HFT. If you are the kind of person who cuts corners and blatantly disregards their own safety, go somewhere else. Then, set the bottle jack on top of the center slide and add 4 springs, 2 on each side. We first gathered product information from reliable sources using the algorithms we had created. Among them are: Why would you purchase a cheap brand that is unable to meet your expectations? 2022 HOME | Conch House Marina | St. Augustine, FL Built with, Square Tubing Roller Dies,Compatible With, Top 10 Best Delta 50 345 3 Reviews In 2022, We currently have 67 different Die Sets in stock, Each die set is 100% CNC machined out of 1018 steel for a precise fit, Due to many operator controlled variables there is no warranty on our dies, IF ROLLING MATERIAL 1.5 AND LARGER; PLEASE SEE RECOMENDED UPGRADES IN THE DESCRIPTION BELOW, 1 Square Tube Roller for TR50,1-1/4 Square Tube Roller for TR50, 1-1/2 Square Tubing Roller for TR50, 1-3/4 Square Tube Roller for TR50. My roller features multiple locations to place the bottom dies, allowing you to place them farther apart for larger radii, which in turn requires less effort to do the rolling. Clamp the tracks in place, make sure the center slide can freely slide up and down the entire length of the tracks, and drill 4 equally spaced 3/8" holes in each one. 9999.11 Maximum Capacity U.S. There are 2 ways in which you can mate the drive die to the drive shaft, one of which is to cut an interior keyway and use a square key to mate with the shaft. Kaka Industrial TR-40 Tubing Rolling Bender Maximum capacity is up to 1-1/2 "x 14 gauge square tubes with multiple passes.For Mild Steel Cooper and Aluminum,Manual Square and Rectangular Tube Bender, Spare part for KAKA Industrial TR-40 Square and Rectangular Tube roll Bender, KAKA TR-60L Manual Tube Pipe Roller Bender, High Precision Tubing Pipe Bender WITHOUT Rollers. Specifically how are window well covers with angle iron bent symmetrically. No Power Outage Risk! B2-20120091-4. I recommend clamping it in place and drilling holes through both the top part and the side plates at the same time to ensure that the holes line up. The handle features a large for more comfort. Don't worry, your details are safe with us. You will enjoy faster opening times, better quality, and a better view by paying more for your product. Once you finish tapping all the bolt holes, test fit the 3 pieces of the center slide. I accidentally didn't drill the holes deep enough, and so I had to use several washers as spacers to let the bolts tighten up. And The metal bending tool is made of A3 high-hardness steel; it can be used for a long time. Our goal is to showcase products from a select few, if not more, trustworthy sellers. We would appreciate your input. Be sure not to twist the saw from side to side at all, or the blade can bind in the cut, mess things up, break teeth on the blade, throw the saw out of the cut, etc. I would make and use something like this: to turn my dies BUT it wouldn't be hand operated!!  Then cut (slowly) as you normally would until you finish the cut, let the blade come to a complete stop, and raise the saw out of the workpiece. Floor-Type Metal Bender: This heavy-duty compact steel pedestal floor bender has a 1-inch to 3-inch working capacity.

Then cut (slowly) as you normally would until you finish the cut, let the blade come to a complete stop, and raise the saw out of the workpiece. Floor-Type Metal Bender: This heavy-duty compact steel pedestal floor bender has a 1-inch to 3-inch working capacity.

Therefore I will tell you, for example, "use a right hand turning tool" or "cut .020" at a time," but I will not tell you what a right hand turning tool is, or how to read, zero out, or use the dials to make a .020" cut. Yes, I will be buying or making one of those soon. They are actually one of the easier die sets to make, as they don't require cutting a curve like the round tubing dies do. All these are made of reinforced steel for durable use. Balusters, Cast Iron & Steel Deco Components, Skip to the beginning of the images gallery, Copyright Jansen Supply Co. All rights reserved 2020, Bends square tubing up to 2 x 2 x 11 ga., rectangular up to 1 x 2 The Hard Way.

Therefore I will tell you, for example, "use a right hand turning tool" or "cut .020" at a time," but I will not tell you what a right hand turning tool is, or how to read, zero out, or use the dials to make a .020" cut. Yes, I will be buying or making one of those soon. They are actually one of the easier die sets to make, as they don't require cutting a curve like the round tubing dies do. All these are made of reinforced steel for durable use. Balusters, Cast Iron & Steel Deco Components, Skip to the beginning of the images gallery, Copyright Jansen Supply Co. All rights reserved 2020, Bends square tubing up to 2 x 2 x 11 ga., rectangular up to 1 x 2 The Hard Way.  Something went wrong. Our company aims for products which provide greater value than the standard, but with a good balance between square tubing roller dies. Now we need to cut out holes in the side pieces to reduce the weight of the machine (and because it looks cool). However, to get you started, I will walk you through how to make a 1 1/2" round tubing die. I use Draft Sight a free easy to use 2D drafting software that is compatible with AutoCAD. In order to eliminate confusion, I have both taken pictures and made technical drawings of the various parts, when the technical drawings and pictures conflict, the dimensions and locations on the drawings always override those in the pictures. Reply Submit Your Inquiry Tube Pipe Rolling Bender and Tube Die Set, Compact and Powerful Internal On/Off Switch N0 Electricity Required! Then, flip it over and add 2 bearings, one on each side, in the location of your choice. Universal Usage: A multifunctional steel bender machine produces grids, gates, balcony railing, patio furniture, iron lamps, power construction, road building, bridges pipeline laying or repairing, etc. Tmall Taobao World If youre looking for a company that can provide quality support. Simply insert the end of the tubing between the dies and start cranking the turning handle. Lets continue! Now cut out pieces for the center slide. I was hoping their might be a set of dies you could make for something like this to do it, but my googling hasn't resulted in anything detailed enough. Measuring units, Measures in feet and inches. Now cut two 9" pieces and one 18" piece of 3/4" shaft, then slide the 9" pieces in place between the side bearings and the 18" piece into the center slide. | Suppliers In this instructable, I will be showing you how to build a roller-bender machine from scratch.

Something went wrong. Our company aims for products which provide greater value than the standard, but with a good balance between square tubing roller dies. Now we need to cut out holes in the side pieces to reduce the weight of the machine (and because it looks cool). However, to get you started, I will walk you through how to make a 1 1/2" round tubing die. I use Draft Sight a free easy to use 2D drafting software that is compatible with AutoCAD. In order to eliminate confusion, I have both taken pictures and made technical drawings of the various parts, when the technical drawings and pictures conflict, the dimensions and locations on the drawings always override those in the pictures. Reply Submit Your Inquiry Tube Pipe Rolling Bender and Tube Die Set, Compact and Powerful Internal On/Off Switch N0 Electricity Required! Then, flip it over and add 2 bearings, one on each side, in the location of your choice. Universal Usage: A multifunctional steel bender machine produces grids, gates, balcony railing, patio furniture, iron lamps, power construction, road building, bridges pipeline laying or repairing, etc. Tmall Taobao World If youre looking for a company that can provide quality support. Simply insert the end of the tubing between the dies and start cranking the turning handle. Lets continue! Now cut out pieces for the center slide. I was hoping their might be a set of dies you could make for something like this to do it, but my googling hasn't resulted in anything detailed enough. Measuring units, Measures in feet and inches. Now cut two 9" pieces and one 18" piece of 3/4" shaft, then slide the 9" pieces in place between the side bearings and the 18" piece into the center slide. | Suppliers In this instructable, I will be showing you how to build a roller-bender machine from scratch.  Once you put together whatever crank you're using, slide it into the bearings in the center slide, and you'll have finished the body of the roller-bender. For the crank, I decided to re-use the crank wheel from the harbor freight tubing roller. 33 stand supports the large baseplate, which allows for a stable bending process. Oversized, and it won't fit; undersized, and it won't work properly. 7075 is harder than 6061 but unless hard anodized will still be pretty softI would think they will wear very quickly and have a series of flats if used with steel tube?

Once you put together whatever crank you're using, slide it into the bearings in the center slide, and you'll have finished the body of the roller-bender. For the crank, I decided to re-use the crank wheel from the harbor freight tubing roller. 33 stand supports the large baseplate, which allows for a stable bending process. Oversized, and it won't fit; undersized, and it won't work properly. 7075 is harder than 6061 but unless hard anodized will still be pretty softI would think they will wear very quickly and have a series of flats if used with steel tube?

- Adjustable lock collars to keep material aligned. Tap the holes in the large thick piece with a 3/8-16 tap, and assemble the top piece as shown in the last 3 images. Drill two 5/16" holes 1" deep in both ends of each piece, and thread them with a 3/8-16tap. Adopts a precise gear structure design with an accuracy of0.5%. Now use 4 pieces of 1" by 1/4" by 1" aluminum bar stock to make tracks for the center slide to slide in. Your reasonable suggestions will be taken into consideration as we make corrections to our list. Our top rated square tubing roller dies list excludes products that received mostly negative reviews. Also, it is important to make sure that both side pieces are as close to identical as possible, otherwise it will create problems later. Be sure to wear a face shield and gloves when cutting the aluminum, as the chips tend to fly everywhere and can be quite sharp. Terms of Use You get what you pay for, according to an old saying. on Step 33. | Showroom Then, if you haven't already, add the tracks for the center slide. High Flexibility: With adjustable roller for flexibility and easy operation.

- Adjustable lock collars to keep material aligned. Tap the holes in the large thick piece with a 3/8-16 tap, and assemble the top piece as shown in the last 3 images. Drill two 5/16" holes 1" deep in both ends of each piece, and thread them with a 3/8-16tap. Adopts a precise gear structure design with an accuracy of0.5%. Now use 4 pieces of 1" by 1/4" by 1" aluminum bar stock to make tracks for the center slide to slide in. Your reasonable suggestions will be taken into consideration as we make corrections to our list. Our top rated square tubing roller dies list excludes products that received mostly negative reviews. Also, it is important to make sure that both side pieces are as close to identical as possible, otherwise it will create problems later. Be sure to wear a face shield and gloves when cutting the aluminum, as the chips tend to fly everywhere and can be quite sharp. Terms of Use You get what you pay for, according to an old saying. on Step 33. | Showroom Then, if you haven't already, add the tracks for the center slide. High Flexibility: With adjustable roller for flexibility and easy operation.  This will allow the bolts to pull the pieces more tightly together. As part of our goal to provide the best experience to our readers, we have added a final layer of filtering. Conch-House.comis a participant in the Amazon Associate program and will earn from qualifying purchases. First, use 7/16" bolts to mount the bearings to the side plates as shown in the first 3 images, then mount the side plates to the top plate. It is only through thorough research that one can come across the best products. Very slowly, tilt the saw down and back until the blade makes contact with the workpiece, and continue slowly lowering the blade until it cuts all the way through the workpiece. Use a 1/4-20 tap to thread the holes, and screw 1/4" by 1"bolts and nuts into the holes. If you build just the roller, you can easily do it for around $300-400. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. Now that you have a temporary handle for your roller, you can roll your own crank wheel for a more elegant-looking one, or just leave it the way it is. ), 6 - flange block bearing (I used UCF204-12), Various nuts, bolts, lock washers, and washers, sizes 1/4", 3/8", and 7/16", Lathe tooling for boring, facing, drilling, and other standard operations, Drill press or Vertical milling machine with tooling for drilling, Precision calipers (accurate to .001" is fine), Basic knowledge of how to use a lathe without killing yourself. Also, if you disregard my warnings and stupidly attempt to do this project even though you don't know what you're doing, I am not responsible for you cutting off fingers or killing yourself as a result. It takes practice, but just go slowly and don't cut too deep; you should be fine. The metal bender is well-built and lightweight; you can mount it on work trucks, tractors, or concrete floors. Well Constructed: Adopts triangular base and thickened screw rod for ease of use & stability during bending process. your better off bending then 'barrel' plating a batchChrome plating will probably flake off on inside of bend and crack on outside radius Chrome doesn't like being compressed or stretched, Tip

This will allow the bolts to pull the pieces more tightly together. As part of our goal to provide the best experience to our readers, we have added a final layer of filtering. Conch-House.comis a participant in the Amazon Associate program and will earn from qualifying purchases. First, use 7/16" bolts to mount the bearings to the side plates as shown in the first 3 images, then mount the side plates to the top plate. It is only through thorough research that one can come across the best products. Very slowly, tilt the saw down and back until the blade makes contact with the workpiece, and continue slowly lowering the blade until it cuts all the way through the workpiece. Use a 1/4-20 tap to thread the holes, and screw 1/4" by 1"bolts and nuts into the holes. If you build just the roller, you can easily do it for around $300-400. - User Information Legal Enquiry Guide, 1999-2022 Alibaba.com. Now that you have a temporary handle for your roller, you can roll your own crank wheel for a more elegant-looking one, or just leave it the way it is. ), 6 - flange block bearing (I used UCF204-12), Various nuts, bolts, lock washers, and washers, sizes 1/4", 3/8", and 7/16", Lathe tooling for boring, facing, drilling, and other standard operations, Drill press or Vertical milling machine with tooling for drilling, Precision calipers (accurate to .001" is fine), Basic knowledge of how to use a lathe without killing yourself. Also, if you disregard my warnings and stupidly attempt to do this project even though you don't know what you're doing, I am not responsible for you cutting off fingers or killing yourself as a result. It takes practice, but just go slowly and don't cut too deep; you should be fine. The metal bender is well-built and lightweight; you can mount it on work trucks, tractors, or concrete floors. Well Constructed: Adopts triangular base and thickened screw rod for ease of use & stability during bending process. your better off bending then 'barrel' plating a batchChrome plating will probably flake off on inside of bend and crack on outside radius Chrome doesn't like being compressed or stretched, Tip  The dies were actually the best part of the HF roller, I am temporarily reusing some of them until I get around to making full sets. Now it's time to drill holes so that we can bolt together the pieces of the center slide. Bending Angle Round Tube, Square Tube, Pipe Bending Machine Stainless Steel Carbon Steel Roller Pipe Bending Machine Mandrel Square Tube Rectangular Pipe Bender, Automatic Hydraulic Stainless Steel Ring Pipe Bending Machine Electric Single Head Hydraulic 3D Roller Square Tube Bender, Tube hydraulic steel pipe bender 1/2 roller bending machine moulds square parts electric manufacturer in china for tubes, High precisioncnc rebar coil bender machine stirrup Steel pipe profile bending forming spiral steel large pipe coiling machine, Rotary bender cnc tube pipe bender thin wall square tube tubing pipe roller bender, CA-129 Electric rolling pipe bender machine,tube bending machine three roller bending machine, 2021 New For Sale Moffler Craigslist Die For 6inch Cercll Tubing Roller Wg 76 Pipe Tube Bender, Heavy duty automatic gi conduit round square ss roller with mandril hydraulic air conditioner cnc tube pipe bender for sale, TR-60 TTMC Brand New Tube Rollers, Tube & Pipe Rollers, Radius Bender, hot sale competitive price 3 axis hydraulic 3 roller 360 degree cnc pipe profile bending machine, Hydraulic Tube Bending Machine HRBM65 HRBM65HV, metal pipe bending machine WG-51 pipe bender in china roller pipe bender, latest design electric tube bending machine for pipe and tube parts, Square Metal Pipe Tube Bending Machine Tube Bender, HW38/50/75 display rackes indicators Electric steel pipe tube bender manual bending machine, Square Tube Bender and Ring Roller Aluminum Arc Bending Machine for Sale, Section Bending Machine W24S Pipe Bender / Angle / Square Tube Bending Machine, High Power square tube Steel Pipes profile tube bender Hydraulic 3 Roll Pipe Bending Machine, JY-50 high quality sheet metal circular duct tube electric vertical angle roll bender, steel bar tube bender machines square pipe bending machine stainless steel pipe round pipe bender, Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Hook the springs on the 1/4" bolts. In order to ensure the best fit possible, use the center slide as a spacer to line up your tracks (theoretically, if your cuts were perfect, the outer edges of the tracks would line up with the triangular holes in the side plates, but my cuts were not perfect, and I doubt yours are either unless you used a CNC cutter). In addition, drill 2 holes in the center of each side piece, also 1" in diameter. Now, use right angle clamps to hold together 3 of the pieces as shown in the first image, and drill two 5/16" holes through each 1/2" thick piece and into the sides of the 1" thick piece. Then, again, for the (less than the) price if the 1/2" aluminum plate, there is HFT. If you are the kind of person who cuts corners and blatantly disregards their own safety, go somewhere else. Then, set the bottle jack on top of the center slide and add 4 springs, 2 on each side. We first gathered product information from reliable sources using the algorithms we had created. Among them are: Why would you purchase a cheap brand that is unable to meet your expectations? 2022 HOME | Conch House Marina | St. Augustine, FL Built with, Square Tubing Roller Dies,Compatible With, Top 10 Best Delta 50 345 3 Reviews In 2022, We currently have 67 different Die Sets in stock, Each die set is 100% CNC machined out of 1018 steel for a precise fit, Due to many operator controlled variables there is no warranty on our dies, IF ROLLING MATERIAL 1.5 AND LARGER; PLEASE SEE RECOMENDED UPGRADES IN THE DESCRIPTION BELOW, 1 Square Tube Roller for TR50,1-1/4 Square Tube Roller for TR50, 1-1/2 Square Tubing Roller for TR50, 1-3/4 Square Tube Roller for TR50. My roller features multiple locations to place the bottom dies, allowing you to place them farther apart for larger radii, which in turn requires less effort to do the rolling. Clamp the tracks in place, make sure the center slide can freely slide up and down the entire length of the tracks, and drill 4 equally spaced 3/8" holes in each one. 9999.11 Maximum Capacity U.S. There are 2 ways in which you can mate the drive die to the drive shaft, one of which is to cut an interior keyway and use a square key to mate with the shaft. Kaka Industrial TR-40 Tubing Rolling Bender Maximum capacity is up to 1-1/2 "x 14 gauge square tubes with multiple passes.For Mild Steel Cooper and Aluminum,Manual Square and Rectangular Tube Bender, Spare part for KAKA Industrial TR-40 Square and Rectangular Tube roll Bender, KAKA TR-60L Manual Tube Pipe Roller Bender, High Precision Tubing Pipe Bender WITHOUT Rollers. Specifically how are window well covers with angle iron bent symmetrically. No Power Outage Risk! B2-20120091-4. I recommend clamping it in place and drilling holes through both the top part and the side plates at the same time to ensure that the holes line up. The handle features a large for more comfort. Don't worry, your details are safe with us. You will enjoy faster opening times, better quality, and a better view by paying more for your product. Once you finish tapping all the bolt holes, test fit the 3 pieces of the center slide. I accidentally didn't drill the holes deep enough, and so I had to use several washers as spacers to let the bolts tighten up. And The metal bending tool is made of A3 high-hardness steel; it can be used for a long time. Our goal is to showcase products from a select few, if not more, trustworthy sellers. We would appreciate your input. Be sure not to twist the saw from side to side at all, or the blade can bind in the cut, mess things up, break teeth on the blade, throw the saw out of the cut, etc. I would make and use something like this: to turn my dies BUT it wouldn't be hand operated!!

The dies were actually the best part of the HF roller, I am temporarily reusing some of them until I get around to making full sets. Now it's time to drill holes so that we can bolt together the pieces of the center slide. Bending Angle Round Tube, Square Tube, Pipe Bending Machine Stainless Steel Carbon Steel Roller Pipe Bending Machine Mandrel Square Tube Rectangular Pipe Bender, Automatic Hydraulic Stainless Steel Ring Pipe Bending Machine Electric Single Head Hydraulic 3D Roller Square Tube Bender, Tube hydraulic steel pipe bender 1/2 roller bending machine moulds square parts electric manufacturer in china for tubes, High precisioncnc rebar coil bender machine stirrup Steel pipe profile bending forming spiral steel large pipe coiling machine, Rotary bender cnc tube pipe bender thin wall square tube tubing pipe roller bender, CA-129 Electric rolling pipe bender machine,tube bending machine three roller bending machine, 2021 New For Sale Moffler Craigslist Die For 6inch Cercll Tubing Roller Wg 76 Pipe Tube Bender, Heavy duty automatic gi conduit round square ss roller with mandril hydraulic air conditioner cnc tube pipe bender for sale, TR-60 TTMC Brand New Tube Rollers, Tube & Pipe Rollers, Radius Bender, hot sale competitive price 3 axis hydraulic 3 roller 360 degree cnc pipe profile bending machine, Hydraulic Tube Bending Machine HRBM65 HRBM65HV, metal pipe bending machine WG-51 pipe bender in china roller pipe bender, latest design electric tube bending machine for pipe and tube parts, Square Metal Pipe Tube Bending Machine Tube Bender, HW38/50/75 display rackes indicators Electric steel pipe tube bender manual bending machine, Square Tube Bender and Ring Roller Aluminum Arc Bending Machine for Sale, Section Bending Machine W24S Pipe Bender / Angle / Square Tube Bending Machine, High Power square tube Steel Pipes profile tube bender Hydraulic 3 Roll Pipe Bending Machine, JY-50 high quality sheet metal circular duct tube electric vertical angle roll bender, steel bar tube bender machines square pipe bending machine stainless steel pipe round pipe bender, Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Hook the springs on the 1/4" bolts. In order to ensure the best fit possible, use the center slide as a spacer to line up your tracks (theoretically, if your cuts were perfect, the outer edges of the tracks would line up with the triangular holes in the side plates, but my cuts were not perfect, and I doubt yours are either unless you used a CNC cutter). In addition, drill 2 holes in the center of each side piece, also 1" in diameter. Now, use right angle clamps to hold together 3 of the pieces as shown in the first image, and drill two 5/16" holes through each 1/2" thick piece and into the sides of the 1" thick piece. Then, again, for the (less than the) price if the 1/2" aluminum plate, there is HFT. If you are the kind of person who cuts corners and blatantly disregards their own safety, go somewhere else. Then, set the bottle jack on top of the center slide and add 4 springs, 2 on each side. We first gathered product information from reliable sources using the algorithms we had created. Among them are: Why would you purchase a cheap brand that is unable to meet your expectations? 2022 HOME | Conch House Marina | St. Augustine, FL Built with, Square Tubing Roller Dies,Compatible With, Top 10 Best Delta 50 345 3 Reviews In 2022, We currently have 67 different Die Sets in stock, Each die set is 100% CNC machined out of 1018 steel for a precise fit, Due to many operator controlled variables there is no warranty on our dies, IF ROLLING MATERIAL 1.5 AND LARGER; PLEASE SEE RECOMENDED UPGRADES IN THE DESCRIPTION BELOW, 1 Square Tube Roller for TR50,1-1/4 Square Tube Roller for TR50, 1-1/2 Square Tubing Roller for TR50, 1-3/4 Square Tube Roller for TR50. My roller features multiple locations to place the bottom dies, allowing you to place them farther apart for larger radii, which in turn requires less effort to do the rolling. Clamp the tracks in place, make sure the center slide can freely slide up and down the entire length of the tracks, and drill 4 equally spaced 3/8" holes in each one. 9999.11 Maximum Capacity U.S. There are 2 ways in which you can mate the drive die to the drive shaft, one of which is to cut an interior keyway and use a square key to mate with the shaft. Kaka Industrial TR-40 Tubing Rolling Bender Maximum capacity is up to 1-1/2 "x 14 gauge square tubes with multiple passes.For Mild Steel Cooper and Aluminum,Manual Square and Rectangular Tube Bender, Spare part for KAKA Industrial TR-40 Square and Rectangular Tube roll Bender, KAKA TR-60L Manual Tube Pipe Roller Bender, High Precision Tubing Pipe Bender WITHOUT Rollers. Specifically how are window well covers with angle iron bent symmetrically. No Power Outage Risk! B2-20120091-4. I recommend clamping it in place and drilling holes through both the top part and the side plates at the same time to ensure that the holes line up. The handle features a large for more comfort. Don't worry, your details are safe with us. You will enjoy faster opening times, better quality, and a better view by paying more for your product. Once you finish tapping all the bolt holes, test fit the 3 pieces of the center slide. I accidentally didn't drill the holes deep enough, and so I had to use several washers as spacers to let the bolts tighten up. And The metal bending tool is made of A3 high-hardness steel; it can be used for a long time. Our goal is to showcase products from a select few, if not more, trustworthy sellers. We would appreciate your input. Be sure not to twist the saw from side to side at all, or the blade can bind in the cut, mess things up, break teeth on the blade, throw the saw out of the cut, etc. I would make and use something like this: to turn my dies BUT it wouldn't be hand operated!!  Then cut (slowly) as you normally would until you finish the cut, let the blade come to a complete stop, and raise the saw out of the workpiece. Floor-Type Metal Bender: This heavy-duty compact steel pedestal floor bender has a 1-inch to 3-inch working capacity.

Then cut (slowly) as you normally would until you finish the cut, let the blade come to a complete stop, and raise the saw out of the workpiece. Floor-Type Metal Bender: This heavy-duty compact steel pedestal floor bender has a 1-inch to 3-inch working capacity.