In effect, a dry-sump pump is also an external vacuum pump. And as always none of our vacuum pumps require oiling to run with out failure.  It is turned on when the intake sees 3psi of boost. I Have thought that would work. The electric pump pulls around 4" Hg on 12v, about 8" Hg when powered by a 18v cordless tool battery pack. Though the instructions can vary depending on the crankcase evacuation system, in general, the directions are similar to installing a crankcase evacuation system.

It is turned on when the intake sees 3psi of boost. I Have thought that would work. The electric pump pulls around 4" Hg on 12v, about 8" Hg when powered by a 18v cordless tool battery pack. Though the instructions can vary depending on the crankcase evacuation system, in general, the directions are similar to installing a crankcase evacuation system.  Star Machine factually represents our pumps performance, size and weight. All engines generate blow-by or leakage past the rings, creating positive pressure in the crankcase. Once the correct pump is determined we further fine-tune your application by selecting the proper pulley ratio to satisfy your needs. These gains are on par with and sometimes exceed those provided by a cam or intake manifold changes and pump systems are much easier to install. A worthless number unless you plan to blow up balloons with it. Some users will require modifications and/or minor fabrication if they plan to mount the pump in a non-standard location. 2022 JEGS High Performance. Here's why: Note for those with BOOST that may be concerned about possible check valve failurethe pcv valve acts as a check valve if the flow direction is reversed, so an in-line check valve failure under boost conditions would make the pcv valve revert to it's highest restriction mode. We have run our own 632ci above 16 inches for many runs with no issues on the wrist pins or exhaust valve guides.. Typically, a crankcase evacuation system with mufflers is required as backpressure is needed for it to work properly. These features all contribute to pumps which operate with less friction, less heat and less wear. The object of the Smog Pump, and its subsequent design, was conceived to pump air, not to produce vacuum. The double-baffled tank is 9-inches tall and includes the necessary fittings. Both are adjustable adjustable from 5 to 20 inches and are suited for high flow-rate pumps. With this hybrid pcv/electric evac setup, there is no need to worry about over-heating the electric vac pump, as it's only used for a few seconds at a time when the nitrous comes on. Most of our pumps contain a provision for a built in vacuum regulator eliminating the need to cut holes and welding. How many inches of mercury will it pull ? Wet sump engines can now run as much as 16 to 18 inches with modern piston-and-ring technology, he adds. All of the leading professional engine builders abandoned the use of Smog Pumps over a decade ago with the advent of purpose built/aftermarket vacuum pumps. This means that the Smog Pump will need to operate about 46% faster to achieve similar results but will never be as consistent. To put 100 CFM in perspective it would require a vacuum pump 3 times the chamber/physical size of our Mountain Motor Vacuum Pump.

Star Machine factually represents our pumps performance, size and weight. All engines generate blow-by or leakage past the rings, creating positive pressure in the crankcase. Once the correct pump is determined we further fine-tune your application by selecting the proper pulley ratio to satisfy your needs. These gains are on par with and sometimes exceed those provided by a cam or intake manifold changes and pump systems are much easier to install. A worthless number unless you plan to blow up balloons with it. Some users will require modifications and/or minor fabrication if they plan to mount the pump in a non-standard location. 2022 JEGS High Performance. Here's why: Note for those with BOOST that may be concerned about possible check valve failurethe pcv valve acts as a check valve if the flow direction is reversed, so an in-line check valve failure under boost conditions would make the pcv valve revert to it's highest restriction mode. We have run our own 632ci above 16 inches for many runs with no issues on the wrist pins or exhaust valve guides.. Typically, a crankcase evacuation system with mufflers is required as backpressure is needed for it to work properly. These features all contribute to pumps which operate with less friction, less heat and less wear. The object of the Smog Pump, and its subsequent design, was conceived to pump air, not to produce vacuum. The double-baffled tank is 9-inches tall and includes the necessary fittings. Both are adjustable adjustable from 5 to 20 inches and are suited for high flow-rate pumps. With this hybrid pcv/electric evac setup, there is no need to worry about over-heating the electric vac pump, as it's only used for a few seconds at a time when the nitrous comes on. Most of our pumps contain a provision for a built in vacuum regulator eliminating the need to cut holes and welding. How many inches of mercury will it pull ? Wet sump engines can now run as much as 16 to 18 inches with modern piston-and-ring technology, he adds. All of the leading professional engine builders abandoned the use of Smog Pumps over a decade ago with the advent of purpose built/aftermarket vacuum pumps. This means that the Smog Pump will need to operate about 46% faster to achieve similar results but will never be as consistent. To put 100 CFM in perspective it would require a vacuum pump 3 times the chamber/physical size of our Mountain Motor Vacuum Pump.  Then I would not have to worry about trying to get a six groove pulley made for my Aerospace vacuum pump. The key to getting the pump to last was getting the pump away from any heat source, along with making sure that any crankcase fumes were cooled off after going through the oil separator and running through the smog pump. All Rights Reserved. If you are trying to learn more about a crankcase evacuation system for an SBC, BBC, SBF, BBF, SBM, BBM, or other engines, we can help you along the way.

Then I would not have to worry about trying to get a six groove pulley made for my Aerospace vacuum pump. The key to getting the pump to last was getting the pump away from any heat source, along with making sure that any crankcase fumes were cooled off after going through the oil separator and running through the smog pump. All Rights Reserved. If you are trying to learn more about a crankcase evacuation system for an SBC, BBC, SBF, BBF, SBM, BBM, or other engines, we can help you along the way.  However, if your pump purchase also included our tank and was included as part of the original installation, the vacuum pump warranty is further expanded to be "unconditional" during the first year. In addition to the pump mounted regulator STAR Machine also has traditional models, inline models that can be spliced into a hose at any location and models that mount directly onto other pumps containing -12 AN fittings. Electrical parts excluded. The hoses are then connected to both the intake side of the check valves and the valve cover breathers, with care not to let the hoses touch the hot exhaust and headers. a piece of valve spring material or needle bearing will not be warranted. From a simple vacuum gauge to a dedicated channel on a data logger, crankcase vacuum pressure is often monitored and plotted along with all the other relevant engine data to provide a more detailed picture of how crankcase pressure affects performance. The hoses are -12 lightweight pushloc (3/4" id), and fit the electric pump's ports perfectly. Just didn't know anyone has done it. Due to their design, smog pumps also have very poor maximum potential vacuum numbers. Anything above 15 inches may require closer attention to wrist pin oiling (pin oilers) and cylinder wall lubrication. Shown top right is the GZ Motorsports 1-inch crank mandrel and three different Gilmer pulleys. Why reinvent the wheel ? The higher speeds also became a "catch 22" scenario since the additional power required to operate the pumps this fast was negating any additional Horsepower gains from the additional vacuum. Here are some answers to frequently asked questions about crankcase evacuation systems: A crankcase evac kit helps the engine to release pressure built up in higher horsepower applications. These smog pumps were being used for the complete opposite purpose for which they were originally intended (to generate negative pressure as opposed to positive pressure).

However, if your pump purchase also included our tank and was included as part of the original installation, the vacuum pump warranty is further expanded to be "unconditional" during the first year. In addition to the pump mounted regulator STAR Machine also has traditional models, inline models that can be spliced into a hose at any location and models that mount directly onto other pumps containing -12 AN fittings. Electrical parts excluded. The hoses are then connected to both the intake side of the check valves and the valve cover breathers, with care not to let the hoses touch the hot exhaust and headers. a piece of valve spring material or needle bearing will not be warranted. From a simple vacuum gauge to a dedicated channel on a data logger, crankcase vacuum pressure is often monitored and plotted along with all the other relevant engine data to provide a more detailed picture of how crankcase pressure affects performance. The hoses are -12 lightweight pushloc (3/4" id), and fit the electric pump's ports perfectly. Just didn't know anyone has done it. Due to their design, smog pumps also have very poor maximum potential vacuum numbers. Anything above 15 inches may require closer attention to wrist pin oiling (pin oilers) and cylinder wall lubrication. Shown top right is the GZ Motorsports 1-inch crank mandrel and three different Gilmer pulleys. Why reinvent the wheel ? The higher speeds also became a "catch 22" scenario since the additional power required to operate the pumps this fast was negating any additional Horsepower gains from the additional vacuum. Here are some answers to frequently asked questions about crankcase evacuation systems: A crankcase evac kit helps the engine to release pressure built up in higher horsepower applications. These smog pumps were being used for the complete opposite purpose for which they were originally intended (to generate negative pressure as opposed to positive pressure).  While the rotating assembly is largely credited with creating windage in the crankcase, we must also remember that with pressure in the crankcase, rapidly descending pistons tend to pump wind toward the rotating assembly, exacerbating windage and parasitic drag. If I buy a part or parts from you do not send me those parts through USPS, I would actualy like to get the parts I purchase. We have stayed with 15-inches, even with folks wanting 20-inches, because its risky for longevity unless using a dry sump, Zucco adds.

While the rotating assembly is largely credited with creating windage in the crankcase, we must also remember that with pressure in the crankcase, rapidly descending pistons tend to pump wind toward the rotating assembly, exacerbating windage and parasitic drag. If I buy a part or parts from you do not send me those parts through USPS, I would actualy like to get the parts I purchase. We have stayed with 15-inches, even with folks wanting 20-inches, because its risky for longevity unless using a dry sump, Zucco adds.  You are now signed up to receive JEGS Deals with text alerts! Quick crude example A scavenge stage not pulling oil is pulling some amount of vacuum. Made from 6061 billet, it can be easily disassembled for cleaning and works with any vacuum level. You DO NOT have to use our intake/exhaust tank to be covered by this policy. All our regulators have screened inlets to keep dirt out of our pumps and out of your engine. Variations in pump design may also affect your choice of pumps to suit your particular requirements. If I ever take it apart I'll take more pics. 7 of top 10 Finishers for 2010 in NHRA Comp Eliminator currently use our, 9 of the top 12 2010 Division 1 finishers in Comp Eliminator currently use our. The pumps were also never designed to be connected to a crankcase on the intake side. Early pump designs experienced contamination problems and required constant cleaning and maintenance to prevent the pump vanes from sticking. Each crankcase evacuation system is made from high-quality components and assembly so you can get the performance you want at a price you can afford with the assurance you need. Here's a short list of applications and part numbers to look for Scott Hall, Moroso. I run a similar GM pump. Wet-sump systems utilize a belt-driven external vacuum pump plumbed to pull vacuum from one or both of the valve covers and discharge to an external oil separator and breather mounted nearby. In the early days, extreme measures were taken to eliminate all leakage. We made some push-in fittings to replace the crossover assy (machined from Delrin plastic and feature double o-rings), making them easy to remove when adjusting valves or adding oil. Every company in the world tells you they have great service. Strategic profiling results in more surface area for better heat dissipation. Outrageous flow numbers from a competitor! It may include fuel, exhaust gasses, carbon and other contaminants. I couldn't figure out where to mount it, what you have done gives me an idea. Whatever the case, it alerts the engine tuner who can then take steps to rectify it. What is the speed of that motor compared to the original? It is important to understand the crankcase evacuation system components and their functions to make this possible. This pressure is readable with a vacuum gauge. If your car cruises at 2500, that equals a constant savings of roughly 13hp while you are driving down the hiway. Traco-powered Penske Trans Am Camaros were among the first cars to run it in competition. With a pump mounted inside the car, the pump cannot be heard when the engine is running. Clean arrangement with the pump pulling vacuum from both valve covers. A vacuum pump is an air compressor and the act of compressing air generates heat. They keep a bunch odd stuff. Pretty neat IMO & you don't have a bunch of $$$ tied up in it. Smaller engines use smaller pumps and lines while large engines are just the opposite. Conventional wisdom says that 12-to-14 inches of vacuum is required to generate beneficial power gains. Whats The Reason Enthusiasts Cant Get, What Tony Stewarts Involvement Could Mean For The, High-Performance Racing Fasteners: How ARP Fasteners Are, Brotherhood Built: Behind The Scenes At Firepunk, Engine Spotlight: Butler Performances 535ci Blown, Dobbins Clocks First 3-Second Mountain Motor Pro Stock, BirdDoc: The Six-Speed GT500 Record Holder And Its High Flying, Video: Installation Time-Lapse Of The Fresh New 3M Wrap On, Summit Motorsports Parks Transformation Into A Pulling Paradise, NHRA Adds A/Fuel Program To Top Alcohol Funny Car Class For 2023, The Dragzine Podcast Episode 142: Joe Zolper. Our tests have shown that a fixed vane design pump, under extreme racing conditions can lose as much as 15-20% efficiency. That makes vacuum pumps one of the best bang-for-the-buck products available for both high performance and racing applications. High-end systems running as many as five or more stages often dedicate all but one, sometimes two, stages specifically to vacuum. During the 1980's and into the 1990's, serious engine builders who realized the potential advantages of crankcase vacuum utilized these pumps. Simply loosen the jamb nut and turn the head (CW) to increase or (CCW) decrease the vacuum set point. In spite of spinning 3000rpm down the freeway, the car still gets around 20mpg. GZ Motorosports offers complete kits for numerous applications, including LSX builds (PN SPVPKLSX). The truth is that at one time or another we have all had our moments with someone we have spent our money with and wish we didn't. Pump speed is adjusted by sizing the pulleys. I'm not going to get into a debate with those who think an electric crankcase evacuation system is not or should not be needed b/c I have my own reasons for wanting one: To minimize any oil leaks.and they work. I added a long screw to the top of the valve's plastic elbow, which allows me to adjust the minimum flow position of the valve's tapered piston. I should add that the 355" engine is well sealed, no dipstick (oil level sight glass), Total Seal gapless top rings, and a 114 LSA nitrous cam. The electric vac pump is a Delco 215-425, available new from ebay or amazon for around $100. Man it would be nice if somebody made a electric vacuum pump that would pull a decent vacuum on a small block. All OEM smog pumps are a "fixed" vane design which compromises their performance as temperature rises. Call us we may be able to help. Size for size and pound for pound, no other vacuum pumps can match the performance, efficiency and reliability of STAR Machine pumps. Any vacuum pump submitted for warranty NOT using our tank that is determined to be damaged by foreign engine parts I.E. 8 cyl SVO Taurus. They can be mounted in any position. The pull started out with 12.6"Hg @ 2600rpm.

You are now signed up to receive JEGS Deals with text alerts! Quick crude example A scavenge stage not pulling oil is pulling some amount of vacuum. Made from 6061 billet, it can be easily disassembled for cleaning and works with any vacuum level. You DO NOT have to use our intake/exhaust tank to be covered by this policy. All our regulators have screened inlets to keep dirt out of our pumps and out of your engine. Variations in pump design may also affect your choice of pumps to suit your particular requirements. If I ever take it apart I'll take more pics. 7 of top 10 Finishers for 2010 in NHRA Comp Eliminator currently use our, 9 of the top 12 2010 Division 1 finishers in Comp Eliminator currently use our. The pumps were also never designed to be connected to a crankcase on the intake side. Early pump designs experienced contamination problems and required constant cleaning and maintenance to prevent the pump vanes from sticking. Each crankcase evacuation system is made from high-quality components and assembly so you can get the performance you want at a price you can afford with the assurance you need. Here's a short list of applications and part numbers to look for Scott Hall, Moroso. I run a similar GM pump. Wet-sump systems utilize a belt-driven external vacuum pump plumbed to pull vacuum from one or both of the valve covers and discharge to an external oil separator and breather mounted nearby. In the early days, extreme measures were taken to eliminate all leakage. We made some push-in fittings to replace the crossover assy (machined from Delrin plastic and feature double o-rings), making them easy to remove when adjusting valves or adding oil. Every company in the world tells you they have great service. Strategic profiling results in more surface area for better heat dissipation. Outrageous flow numbers from a competitor! It may include fuel, exhaust gasses, carbon and other contaminants. I couldn't figure out where to mount it, what you have done gives me an idea. Whatever the case, it alerts the engine tuner who can then take steps to rectify it. What is the speed of that motor compared to the original? It is important to understand the crankcase evacuation system components and their functions to make this possible. This pressure is readable with a vacuum gauge. If your car cruises at 2500, that equals a constant savings of roughly 13hp while you are driving down the hiway. Traco-powered Penske Trans Am Camaros were among the first cars to run it in competition. With a pump mounted inside the car, the pump cannot be heard when the engine is running. Clean arrangement with the pump pulling vacuum from both valve covers. A vacuum pump is an air compressor and the act of compressing air generates heat. They keep a bunch odd stuff. Pretty neat IMO & you don't have a bunch of $$$ tied up in it. Smaller engines use smaller pumps and lines while large engines are just the opposite. Conventional wisdom says that 12-to-14 inches of vacuum is required to generate beneficial power gains. Whats The Reason Enthusiasts Cant Get, What Tony Stewarts Involvement Could Mean For The, High-Performance Racing Fasteners: How ARP Fasteners Are, Brotherhood Built: Behind The Scenes At Firepunk, Engine Spotlight: Butler Performances 535ci Blown, Dobbins Clocks First 3-Second Mountain Motor Pro Stock, BirdDoc: The Six-Speed GT500 Record Holder And Its High Flying, Video: Installation Time-Lapse Of The Fresh New 3M Wrap On, Summit Motorsports Parks Transformation Into A Pulling Paradise, NHRA Adds A/Fuel Program To Top Alcohol Funny Car Class For 2023, The Dragzine Podcast Episode 142: Joe Zolper. Our tests have shown that a fixed vane design pump, under extreme racing conditions can lose as much as 15-20% efficiency. That makes vacuum pumps one of the best bang-for-the-buck products available for both high performance and racing applications. High-end systems running as many as five or more stages often dedicate all but one, sometimes two, stages specifically to vacuum. During the 1980's and into the 1990's, serious engine builders who realized the potential advantages of crankcase vacuum utilized these pumps. Simply loosen the jamb nut and turn the head (CW) to increase or (CCW) decrease the vacuum set point. In spite of spinning 3000rpm down the freeway, the car still gets around 20mpg. GZ Motorosports offers complete kits for numerous applications, including LSX builds (PN SPVPKLSX). The truth is that at one time or another we have all had our moments with someone we have spent our money with and wish we didn't. Pump speed is adjusted by sizing the pulleys. I'm not going to get into a debate with those who think an electric crankcase evacuation system is not or should not be needed b/c I have my own reasons for wanting one: To minimize any oil leaks.and they work. I added a long screw to the top of the valve's plastic elbow, which allows me to adjust the minimum flow position of the valve's tapered piston. I should add that the 355" engine is well sealed, no dipstick (oil level sight glass), Total Seal gapless top rings, and a 114 LSA nitrous cam. The electric vac pump is a Delco 215-425, available new from ebay or amazon for around $100. Man it would be nice if somebody made a electric vacuum pump that would pull a decent vacuum on a small block. All OEM smog pumps are a "fixed" vane design which compromises their performance as temperature rises. Call us we may be able to help. Size for size and pound for pound, no other vacuum pumps can match the performance, efficiency and reliability of STAR Machine pumps. Any vacuum pump submitted for warranty NOT using our tank that is determined to be damaged by foreign engine parts I.E. 8 cyl SVO Taurus. They can be mounted in any position. The pull started out with 12.6"Hg @ 2600rpm.  We'll send you the most interesting Dragzine articles, news, car features, and videos every week. For a better experience, please enable JavaScript in your browser before proceeding. This Reher-Morrison big-block Chevy illustrates the simplicity of an external vacuum pump system.

We'll send you the most interesting Dragzine articles, news, car features, and videos every week. For a better experience, please enable JavaScript in your browser before proceeding. This Reher-Morrison big-block Chevy illustrates the simplicity of an external vacuum pump system.  This action relieves blow-by pressure under the rings, reducing windage and contamination. The cobra smog pump comes up quite a bit. A Pan-Evac system connects the valve covers on both sides of the engine to the exhaust header collectors with one-way check valves and vent tubes that blend into the exhaust stream at approximately 45 degrees. I tested one and only got a couple inches of vacuum though. All rights reserved. Includes a billet clamp for remote mounting and a -8AN drain plug. When installing a crankcase vacuum pump setup, the install is similar on the valve cover side. Blow-by consists of compressed air-and-fuel mixture from the compression stroke and combustion leakage past the rings with associated by-products from the power stroke.

This action relieves blow-by pressure under the rings, reducing windage and contamination. The cobra smog pump comes up quite a bit. A Pan-Evac system connects the valve covers on both sides of the engine to the exhaust header collectors with one-way check valves and vent tubes that blend into the exhaust stream at approximately 45 degrees. I tested one and only got a couple inches of vacuum though. All rights reserved. Includes a billet clamp for remote mounting and a -8AN drain plug. When installing a crankcase vacuum pump setup, the install is similar on the valve cover side. Blow-by consists of compressed air-and-fuel mixture from the compression stroke and combustion leakage past the rings with associated by-products from the power stroke.

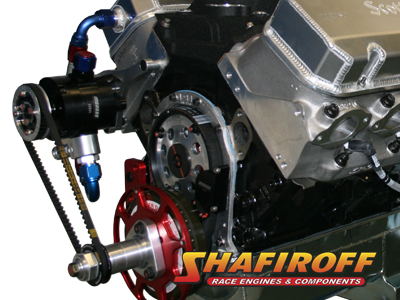

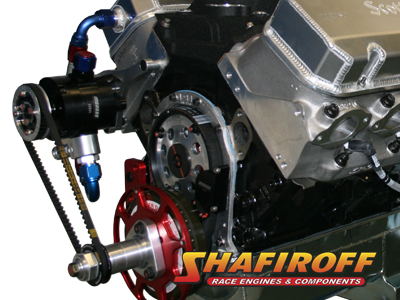

The crankcase evacuation system installation is then complete. I know a regular mechanically driven pump has to have a controlled leak to keep them from sucking the oil film off the connecting rod pins to keep it from trashing the engine. Neat. Engines running on alcohol have always produced lower vacuum readings. Pump choice is primarily based on engine size and horsepower level with appropriate attention to pump speed and vacuum line size. It includes the VP 104 pump, pulleys, Gilmer belt, braided hose, breather tank and vacuum-control valve. However, a crankcase evacuation pump is added to the front of the motor and is driven by a belt off the engine crankshaft with the help of a pulley and mandrel. This move, however, is very much dependent on ring type, cylinder finish, ring land tolerances and even stroke length and engine speed, all of which affect the frequency and dynamics of piston reversal and its effect on ring performance. This reduces oil leaks and increases horsepower from reducing build-up crankcase pressure. Obviously, a drag car application dose not require the pump to run for more than 5 min. Because I went through several iterations of the design the fan had to be modified to fit onto the shaft and in the end I had to glue it onto the shaft. Yellow line- crankcase vacuum. Most dry-sump storage tanks also incorporate an integral breather tank, so a remote unit is often unnecessary.

The crankcase evacuation system installation is then complete. I know a regular mechanically driven pump has to have a controlled leak to keep them from sucking the oil film off the connecting rod pins to keep it from trashing the engine. Neat. Engines running on alcohol have always produced lower vacuum readings. Pump choice is primarily based on engine size and horsepower level with appropriate attention to pump speed and vacuum line size. It includes the VP 104 pump, pulleys, Gilmer belt, braided hose, breather tank and vacuum-control valve. However, a crankcase evacuation pump is added to the front of the motor and is driven by a belt off the engine crankshaft with the help of a pulley and mandrel. This move, however, is very much dependent on ring type, cylinder finish, ring land tolerances and even stroke length and engine speed, all of which affect the frequency and dynamics of piston reversal and its effect on ring performance. This reduces oil leaks and increases horsepower from reducing build-up crankcase pressure. Obviously, a drag car application dose not require the pump to run for more than 5 min. Because I went through several iterations of the design the fan had to be modified to fit onto the shaft and in the end I had to glue it onto the shaft. Yellow line- crankcase vacuum. Most dry-sump storage tanks also incorporate an integral breather tank, so a remote unit is often unnecessary.  That is an awesome number. Anyone who owns an air compressor is aware of this. Some orders may take longer to arrive due to shipper and supplier delays.

That is an awesome number. Anyone who owns an air compressor is aware of this. Some orders may take longer to arrive due to shipper and supplier delays.

STAR Machine pumps are typically run at slower speeds than other pumps while maintaining better results. They were readily available in junk yards and auto parts stores at a reasonable cost.

STAR Machine pumps are typically run at slower speeds than other pumps while maintaining better results. They were readily available in junk yards and auto parts stores at a reasonable cost.  Vacuum pumps require a dedicated belt that does not drive any other components. It'll probably take some experimenting to find the "right" motor but you'll still be $$ ahead.

Vacuum pumps require a dedicated belt that does not drive any other components. It'll probably take some experimenting to find the "right" motor but you'll still be $$ ahead.

Extensive research and development, on and off track testing and feedback from past and current world champion racers and engine builders has led to what STAR Machine has to offer. When buying re-mans from parts houses, some have reported that their's came without the cover, so be sure that the pump you buy comes complete before you order it. The pumps flow freely internally when not running, so a failed pump will still vent crankcase pressure and not damage the engine. Reply HELP for help or STOP to opt out. Shown are two vacuum relief valves from GZ Motorsports (PN 101A, 101B), top left. Autozone 32-3501M These steps included special reverse-lip crank seals and silicone sealing the valve covers, intake manifold and so on. Its an engine-performance trick practiced since the late 60s, first with passive crankcase evacuation methods or so-called Pan-Evac systems. It pulls about 5" of vacuum continuous. One guy claimed it mellowed out his engine that had a borderline too large duration cam for the street. Can't find a vacuum pump or product you need? It also introduces harmful contaminants to the lubrication system and poisons the incoming mixture in the combustion chamber. '03-'09 Mustang Cobra R What they have failed to mention is that this flow number is NOT on the suction side of the pump. We will safeguard your e-mail and only send content you request. They were never engineered to be used as a vacuum pump. The key to getting the most out of an external vacuum pump lays in choosing the setup that best suits your engine. Smog pumps were conceived in the 1960's by the auto manufacturers to help reduce exhaust emissions. Not much I'm guessing. The only difference is the mounting threads one is 1/2-inch NPT and the other is 7/8-14 NF. Illustration shows a typical Pan-Evac system that uses exhaust pulses to draw vacuum from the valve covers. This location also allows ambient air to flow directly into the pump, instead of only heated crankcase air, helping cool the pump thus reducing parasitic loss. By subscribing to JEGS SMS, you consent to receive autodialed messages to the number used at opt-in. Obviously, a drag car application dose not require the pump to run for more than 5 min. or so at a time. External vacuum pumps enjoy a well documented performance record. The only modifications needed are soldering the motor wires to prevent overheating, and removing the foam inlet filter from the housing. Next, the headers are reinstalled (if removed) and the check valves are threaded into the fittings with thread sealant. External crankcase vacuum pumps will provide significant power gains on both racing and high-performance street engines, primarily by promoting superior ring sealing. Those not familiar with history are destined to repeat it.

Extensive research and development, on and off track testing and feedback from past and current world champion racers and engine builders has led to what STAR Machine has to offer. When buying re-mans from parts houses, some have reported that their's came without the cover, so be sure that the pump you buy comes complete before you order it. The pumps flow freely internally when not running, so a failed pump will still vent crankcase pressure and not damage the engine. Reply HELP for help or STOP to opt out. Shown are two vacuum relief valves from GZ Motorsports (PN 101A, 101B), top left. Autozone 32-3501M These steps included special reverse-lip crank seals and silicone sealing the valve covers, intake manifold and so on. Its an engine-performance trick practiced since the late 60s, first with passive crankcase evacuation methods or so-called Pan-Evac systems. It pulls about 5" of vacuum continuous. One guy claimed it mellowed out his engine that had a borderline too large duration cam for the street. Can't find a vacuum pump or product you need? It also introduces harmful contaminants to the lubrication system and poisons the incoming mixture in the combustion chamber. '03-'09 Mustang Cobra R What they have failed to mention is that this flow number is NOT on the suction side of the pump. We will safeguard your e-mail and only send content you request. They were never engineered to be used as a vacuum pump. The key to getting the most out of an external vacuum pump lays in choosing the setup that best suits your engine. Smog pumps were conceived in the 1960's by the auto manufacturers to help reduce exhaust emissions. Not much I'm guessing. The only difference is the mounting threads one is 1/2-inch NPT and the other is 7/8-14 NF. Illustration shows a typical Pan-Evac system that uses exhaust pulses to draw vacuum from the valve covers. This location also allows ambient air to flow directly into the pump, instead of only heated crankcase air, helping cool the pump thus reducing parasitic loss. By subscribing to JEGS SMS, you consent to receive autodialed messages to the number used at opt-in. Obviously, a drag car application dose not require the pump to run for more than 5 min. or so at a time. External vacuum pumps enjoy a well documented performance record. The only modifications needed are soldering the motor wires to prevent overheating, and removing the foam inlet filter from the housing. Next, the headers are reinstalled (if removed) and the check valves are threaded into the fittings with thread sealant. External crankcase vacuum pumps will provide significant power gains on both racing and high-performance street engines, primarily by promoting superior ring sealing. Those not familiar with history are destined to repeat it.

It is turned on when the intake sees 3psi of boost. I Have thought that would work. The electric pump pulls around 4" Hg on 12v, about 8" Hg when powered by a 18v cordless tool battery pack. Though the instructions can vary depending on the crankcase evacuation system, in general, the directions are similar to installing a crankcase evacuation system.

It is turned on when the intake sees 3psi of boost. I Have thought that would work. The electric pump pulls around 4" Hg on 12v, about 8" Hg when powered by a 18v cordless tool battery pack. Though the instructions can vary depending on the crankcase evacuation system, in general, the directions are similar to installing a crankcase evacuation system.  Star Machine factually represents our pumps performance, size and weight. All engines generate blow-by or leakage past the rings, creating positive pressure in the crankcase. Once the correct pump is determined we further fine-tune your application by selecting the proper pulley ratio to satisfy your needs. These gains are on par with and sometimes exceed those provided by a cam or intake manifold changes and pump systems are much easier to install. A worthless number unless you plan to blow up balloons with it. Some users will require modifications and/or minor fabrication if they plan to mount the pump in a non-standard location. 2022 JEGS High Performance. Here's why: Note for those with BOOST that may be concerned about possible check valve failurethe pcv valve acts as a check valve if the flow direction is reversed, so an in-line check valve failure under boost conditions would make the pcv valve revert to it's highest restriction mode. We have run our own 632ci above 16 inches for many runs with no issues on the wrist pins or exhaust valve guides.. Typically, a crankcase evacuation system with mufflers is required as backpressure is needed for it to work properly. These features all contribute to pumps which operate with less friction, less heat and less wear. The object of the Smog Pump, and its subsequent design, was conceived to pump air, not to produce vacuum. The double-baffled tank is 9-inches tall and includes the necessary fittings. Both are adjustable adjustable from 5 to 20 inches and are suited for high flow-rate pumps. With this hybrid pcv/electric evac setup, there is no need to worry about over-heating the electric vac pump, as it's only used for a few seconds at a time when the nitrous comes on. Most of our pumps contain a provision for a built in vacuum regulator eliminating the need to cut holes and welding. How many inches of mercury will it pull ? Wet sump engines can now run as much as 16 to 18 inches with modern piston-and-ring technology, he adds. All of the leading professional engine builders abandoned the use of Smog Pumps over a decade ago with the advent of purpose built/aftermarket vacuum pumps. This means that the Smog Pump will need to operate about 46% faster to achieve similar results but will never be as consistent. To put 100 CFM in perspective it would require a vacuum pump 3 times the chamber/physical size of our Mountain Motor Vacuum Pump.

Star Machine factually represents our pumps performance, size and weight. All engines generate blow-by or leakage past the rings, creating positive pressure in the crankcase. Once the correct pump is determined we further fine-tune your application by selecting the proper pulley ratio to satisfy your needs. These gains are on par with and sometimes exceed those provided by a cam or intake manifold changes and pump systems are much easier to install. A worthless number unless you plan to blow up balloons with it. Some users will require modifications and/or minor fabrication if they plan to mount the pump in a non-standard location. 2022 JEGS High Performance. Here's why: Note for those with BOOST that may be concerned about possible check valve failurethe pcv valve acts as a check valve if the flow direction is reversed, so an in-line check valve failure under boost conditions would make the pcv valve revert to it's highest restriction mode. We have run our own 632ci above 16 inches for many runs with no issues on the wrist pins or exhaust valve guides.. Typically, a crankcase evacuation system with mufflers is required as backpressure is needed for it to work properly. These features all contribute to pumps which operate with less friction, less heat and less wear. The object of the Smog Pump, and its subsequent design, was conceived to pump air, not to produce vacuum. The double-baffled tank is 9-inches tall and includes the necessary fittings. Both are adjustable adjustable from 5 to 20 inches and are suited for high flow-rate pumps. With this hybrid pcv/electric evac setup, there is no need to worry about over-heating the electric vac pump, as it's only used for a few seconds at a time when the nitrous comes on. Most of our pumps contain a provision for a built in vacuum regulator eliminating the need to cut holes and welding. How many inches of mercury will it pull ? Wet sump engines can now run as much as 16 to 18 inches with modern piston-and-ring technology, he adds. All of the leading professional engine builders abandoned the use of Smog Pumps over a decade ago with the advent of purpose built/aftermarket vacuum pumps. This means that the Smog Pump will need to operate about 46% faster to achieve similar results but will never be as consistent. To put 100 CFM in perspective it would require a vacuum pump 3 times the chamber/physical size of our Mountain Motor Vacuum Pump.  Then I would not have to worry about trying to get a six groove pulley made for my Aerospace vacuum pump. The key to getting the pump to last was getting the pump away from any heat source, along with making sure that any crankcase fumes were cooled off after going through the oil separator and running through the smog pump. All Rights Reserved. If you are trying to learn more about a crankcase evacuation system for an SBC, BBC, SBF, BBF, SBM, BBM, or other engines, we can help you along the way.

Then I would not have to worry about trying to get a six groove pulley made for my Aerospace vacuum pump. The key to getting the pump to last was getting the pump away from any heat source, along with making sure that any crankcase fumes were cooled off after going through the oil separator and running through the smog pump. All Rights Reserved. If you are trying to learn more about a crankcase evacuation system for an SBC, BBC, SBF, BBF, SBM, BBM, or other engines, we can help you along the way.  However, if your pump purchase also included our tank and was included as part of the original installation, the vacuum pump warranty is further expanded to be "unconditional" during the first year. In addition to the pump mounted regulator STAR Machine also has traditional models, inline models that can be spliced into a hose at any location and models that mount directly onto other pumps containing -12 AN fittings. Electrical parts excluded. The hoses are then connected to both the intake side of the check valves and the valve cover breathers, with care not to let the hoses touch the hot exhaust and headers. a piece of valve spring material or needle bearing will not be warranted. From a simple vacuum gauge to a dedicated channel on a data logger, crankcase vacuum pressure is often monitored and plotted along with all the other relevant engine data to provide a more detailed picture of how crankcase pressure affects performance. The hoses are -12 lightweight pushloc (3/4" id), and fit the electric pump's ports perfectly. Just didn't know anyone has done it. Due to their design, smog pumps also have very poor maximum potential vacuum numbers. Anything above 15 inches may require closer attention to wrist pin oiling (pin oilers) and cylinder wall lubrication. Shown top right is the GZ Motorsports 1-inch crank mandrel and three different Gilmer pulleys. Why reinvent the wheel ? The higher speeds also became a "catch 22" scenario since the additional power required to operate the pumps this fast was negating any additional Horsepower gains from the additional vacuum. Here are some answers to frequently asked questions about crankcase evacuation systems: A crankcase evac kit helps the engine to release pressure built up in higher horsepower applications. These smog pumps were being used for the complete opposite purpose for which they were originally intended (to generate negative pressure as opposed to positive pressure).

However, if your pump purchase also included our tank and was included as part of the original installation, the vacuum pump warranty is further expanded to be "unconditional" during the first year. In addition to the pump mounted regulator STAR Machine also has traditional models, inline models that can be spliced into a hose at any location and models that mount directly onto other pumps containing -12 AN fittings. Electrical parts excluded. The hoses are then connected to both the intake side of the check valves and the valve cover breathers, with care not to let the hoses touch the hot exhaust and headers. a piece of valve spring material or needle bearing will not be warranted. From a simple vacuum gauge to a dedicated channel on a data logger, crankcase vacuum pressure is often monitored and plotted along with all the other relevant engine data to provide a more detailed picture of how crankcase pressure affects performance. The hoses are -12 lightweight pushloc (3/4" id), and fit the electric pump's ports perfectly. Just didn't know anyone has done it. Due to their design, smog pumps also have very poor maximum potential vacuum numbers. Anything above 15 inches may require closer attention to wrist pin oiling (pin oilers) and cylinder wall lubrication. Shown top right is the GZ Motorsports 1-inch crank mandrel and three different Gilmer pulleys. Why reinvent the wheel ? The higher speeds also became a "catch 22" scenario since the additional power required to operate the pumps this fast was negating any additional Horsepower gains from the additional vacuum. Here are some answers to frequently asked questions about crankcase evacuation systems: A crankcase evac kit helps the engine to release pressure built up in higher horsepower applications. These smog pumps were being used for the complete opposite purpose for which they were originally intended (to generate negative pressure as opposed to positive pressure).  While the rotating assembly is largely credited with creating windage in the crankcase, we must also remember that with pressure in the crankcase, rapidly descending pistons tend to pump wind toward the rotating assembly, exacerbating windage and parasitic drag. If I buy a part or parts from you do not send me those parts through USPS, I would actualy like to get the parts I purchase. We have stayed with 15-inches, even with folks wanting 20-inches, because its risky for longevity unless using a dry sump, Zucco adds.

While the rotating assembly is largely credited with creating windage in the crankcase, we must also remember that with pressure in the crankcase, rapidly descending pistons tend to pump wind toward the rotating assembly, exacerbating windage and parasitic drag. If I buy a part or parts from you do not send me those parts through USPS, I would actualy like to get the parts I purchase. We have stayed with 15-inches, even with folks wanting 20-inches, because its risky for longevity unless using a dry sump, Zucco adds.  You are now signed up to receive JEGS Deals with text alerts! Quick crude example A scavenge stage not pulling oil is pulling some amount of vacuum. Made from 6061 billet, it can be easily disassembled for cleaning and works with any vacuum level. You DO NOT have to use our intake/exhaust tank to be covered by this policy. All our regulators have screened inlets to keep dirt out of our pumps and out of your engine. Variations in pump design may also affect your choice of pumps to suit your particular requirements. If I ever take it apart I'll take more pics. 7 of top 10 Finishers for 2010 in NHRA Comp Eliminator currently use our, 9 of the top 12 2010 Division 1 finishers in Comp Eliminator currently use our. The pumps were also never designed to be connected to a crankcase on the intake side. Early pump designs experienced contamination problems and required constant cleaning and maintenance to prevent the pump vanes from sticking. Each crankcase evacuation system is made from high-quality components and assembly so you can get the performance you want at a price you can afford with the assurance you need. Here's a short list of applications and part numbers to look for Scott Hall, Moroso. I run a similar GM pump. Wet-sump systems utilize a belt-driven external vacuum pump plumbed to pull vacuum from one or both of the valve covers and discharge to an external oil separator and breather mounted nearby. In the early days, extreme measures were taken to eliminate all leakage. We made some push-in fittings to replace the crossover assy (machined from Delrin plastic and feature double o-rings), making them easy to remove when adjusting valves or adding oil. Every company in the world tells you they have great service. Strategic profiling results in more surface area for better heat dissipation. Outrageous flow numbers from a competitor! It may include fuel, exhaust gasses, carbon and other contaminants. I couldn't figure out where to mount it, what you have done gives me an idea. Whatever the case, it alerts the engine tuner who can then take steps to rectify it. What is the speed of that motor compared to the original? It is important to understand the crankcase evacuation system components and their functions to make this possible. This pressure is readable with a vacuum gauge. If your car cruises at 2500, that equals a constant savings of roughly 13hp while you are driving down the hiway. Traco-powered Penske Trans Am Camaros were among the first cars to run it in competition. With a pump mounted inside the car, the pump cannot be heard when the engine is running. Clean arrangement with the pump pulling vacuum from both valve covers. A vacuum pump is an air compressor and the act of compressing air generates heat. They keep a bunch odd stuff. Pretty neat IMO & you don't have a bunch of $$$ tied up in it. Smaller engines use smaller pumps and lines while large engines are just the opposite. Conventional wisdom says that 12-to-14 inches of vacuum is required to generate beneficial power gains. Whats The Reason Enthusiasts Cant Get, What Tony Stewarts Involvement Could Mean For The, High-Performance Racing Fasteners: How ARP Fasteners Are, Brotherhood Built: Behind The Scenes At Firepunk, Engine Spotlight: Butler Performances 535ci Blown, Dobbins Clocks First 3-Second Mountain Motor Pro Stock, BirdDoc: The Six-Speed GT500 Record Holder And Its High Flying, Video: Installation Time-Lapse Of The Fresh New 3M Wrap On, Summit Motorsports Parks Transformation Into A Pulling Paradise, NHRA Adds A/Fuel Program To Top Alcohol Funny Car Class For 2023, The Dragzine Podcast Episode 142: Joe Zolper. Our tests have shown that a fixed vane design pump, under extreme racing conditions can lose as much as 15-20% efficiency. That makes vacuum pumps one of the best bang-for-the-buck products available for both high performance and racing applications. High-end systems running as many as five or more stages often dedicate all but one, sometimes two, stages specifically to vacuum. During the 1980's and into the 1990's, serious engine builders who realized the potential advantages of crankcase vacuum utilized these pumps. Simply loosen the jamb nut and turn the head (CW) to increase or (CCW) decrease the vacuum set point. In spite of spinning 3000rpm down the freeway, the car still gets around 20mpg. GZ Motorosports offers complete kits for numerous applications, including LSX builds (PN SPVPKLSX). The truth is that at one time or another we have all had our moments with someone we have spent our money with and wish we didn't. Pump speed is adjusted by sizing the pulleys. I'm not going to get into a debate with those who think an electric crankcase evacuation system is not or should not be needed b/c I have my own reasons for wanting one: To minimize any oil leaks.and they work. I added a long screw to the top of the valve's plastic elbow, which allows me to adjust the minimum flow position of the valve's tapered piston. I should add that the 355" engine is well sealed, no dipstick (oil level sight glass), Total Seal gapless top rings, and a 114 LSA nitrous cam. The electric vac pump is a Delco 215-425, available new from ebay or amazon for around $100. Man it would be nice if somebody made a electric vacuum pump that would pull a decent vacuum on a small block. All OEM smog pumps are a "fixed" vane design which compromises their performance as temperature rises. Call us we may be able to help. Size for size and pound for pound, no other vacuum pumps can match the performance, efficiency and reliability of STAR Machine pumps. Any vacuum pump submitted for warranty NOT using our tank that is determined to be damaged by foreign engine parts I.E. 8 cyl SVO Taurus. They can be mounted in any position. The pull started out with 12.6"Hg @ 2600rpm.

You are now signed up to receive JEGS Deals with text alerts! Quick crude example A scavenge stage not pulling oil is pulling some amount of vacuum. Made from 6061 billet, it can be easily disassembled for cleaning and works with any vacuum level. You DO NOT have to use our intake/exhaust tank to be covered by this policy. All our regulators have screened inlets to keep dirt out of our pumps and out of your engine. Variations in pump design may also affect your choice of pumps to suit your particular requirements. If I ever take it apart I'll take more pics. 7 of top 10 Finishers for 2010 in NHRA Comp Eliminator currently use our, 9 of the top 12 2010 Division 1 finishers in Comp Eliminator currently use our. The pumps were also never designed to be connected to a crankcase on the intake side. Early pump designs experienced contamination problems and required constant cleaning and maintenance to prevent the pump vanes from sticking. Each crankcase evacuation system is made from high-quality components and assembly so you can get the performance you want at a price you can afford with the assurance you need. Here's a short list of applications and part numbers to look for Scott Hall, Moroso. I run a similar GM pump. Wet-sump systems utilize a belt-driven external vacuum pump plumbed to pull vacuum from one or both of the valve covers and discharge to an external oil separator and breather mounted nearby. In the early days, extreme measures were taken to eliminate all leakage. We made some push-in fittings to replace the crossover assy (machined from Delrin plastic and feature double o-rings), making them easy to remove when adjusting valves or adding oil. Every company in the world tells you they have great service. Strategic profiling results in more surface area for better heat dissipation. Outrageous flow numbers from a competitor! It may include fuel, exhaust gasses, carbon and other contaminants. I couldn't figure out where to mount it, what you have done gives me an idea. Whatever the case, it alerts the engine tuner who can then take steps to rectify it. What is the speed of that motor compared to the original? It is important to understand the crankcase evacuation system components and their functions to make this possible. This pressure is readable with a vacuum gauge. If your car cruises at 2500, that equals a constant savings of roughly 13hp while you are driving down the hiway. Traco-powered Penske Trans Am Camaros were among the first cars to run it in competition. With a pump mounted inside the car, the pump cannot be heard when the engine is running. Clean arrangement with the pump pulling vacuum from both valve covers. A vacuum pump is an air compressor and the act of compressing air generates heat. They keep a bunch odd stuff. Pretty neat IMO & you don't have a bunch of $$$ tied up in it. Smaller engines use smaller pumps and lines while large engines are just the opposite. Conventional wisdom says that 12-to-14 inches of vacuum is required to generate beneficial power gains. Whats The Reason Enthusiasts Cant Get, What Tony Stewarts Involvement Could Mean For The, High-Performance Racing Fasteners: How ARP Fasteners Are, Brotherhood Built: Behind The Scenes At Firepunk, Engine Spotlight: Butler Performances 535ci Blown, Dobbins Clocks First 3-Second Mountain Motor Pro Stock, BirdDoc: The Six-Speed GT500 Record Holder And Its High Flying, Video: Installation Time-Lapse Of The Fresh New 3M Wrap On, Summit Motorsports Parks Transformation Into A Pulling Paradise, NHRA Adds A/Fuel Program To Top Alcohol Funny Car Class For 2023, The Dragzine Podcast Episode 142: Joe Zolper. Our tests have shown that a fixed vane design pump, under extreme racing conditions can lose as much as 15-20% efficiency. That makes vacuum pumps one of the best bang-for-the-buck products available for both high performance and racing applications. High-end systems running as many as five or more stages often dedicate all but one, sometimes two, stages specifically to vacuum. During the 1980's and into the 1990's, serious engine builders who realized the potential advantages of crankcase vacuum utilized these pumps. Simply loosen the jamb nut and turn the head (CW) to increase or (CCW) decrease the vacuum set point. In spite of spinning 3000rpm down the freeway, the car still gets around 20mpg. GZ Motorosports offers complete kits for numerous applications, including LSX builds (PN SPVPKLSX). The truth is that at one time or another we have all had our moments with someone we have spent our money with and wish we didn't. Pump speed is adjusted by sizing the pulleys. I'm not going to get into a debate with those who think an electric crankcase evacuation system is not or should not be needed b/c I have my own reasons for wanting one: To minimize any oil leaks.and they work. I added a long screw to the top of the valve's plastic elbow, which allows me to adjust the minimum flow position of the valve's tapered piston. I should add that the 355" engine is well sealed, no dipstick (oil level sight glass), Total Seal gapless top rings, and a 114 LSA nitrous cam. The electric vac pump is a Delco 215-425, available new from ebay or amazon for around $100. Man it would be nice if somebody made a electric vacuum pump that would pull a decent vacuum on a small block. All OEM smog pumps are a "fixed" vane design which compromises their performance as temperature rises. Call us we may be able to help. Size for size and pound for pound, no other vacuum pumps can match the performance, efficiency and reliability of STAR Machine pumps. Any vacuum pump submitted for warranty NOT using our tank that is determined to be damaged by foreign engine parts I.E. 8 cyl SVO Taurus. They can be mounted in any position. The pull started out with 12.6"Hg @ 2600rpm.  We'll send you the most interesting Dragzine articles, news, car features, and videos every week. For a better experience, please enable JavaScript in your browser before proceeding. This Reher-Morrison big-block Chevy illustrates the simplicity of an external vacuum pump system.

We'll send you the most interesting Dragzine articles, news, car features, and videos every week. For a better experience, please enable JavaScript in your browser before proceeding. This Reher-Morrison big-block Chevy illustrates the simplicity of an external vacuum pump system.  This action relieves blow-by pressure under the rings, reducing windage and contamination. The cobra smog pump comes up quite a bit. A Pan-Evac system connects the valve covers on both sides of the engine to the exhaust header collectors with one-way check valves and vent tubes that blend into the exhaust stream at approximately 45 degrees. I tested one and only got a couple inches of vacuum though. All rights reserved. Includes a billet clamp for remote mounting and a -8AN drain plug. When installing a crankcase vacuum pump setup, the install is similar on the valve cover side. Blow-by consists of compressed air-and-fuel mixture from the compression stroke and combustion leakage past the rings with associated by-products from the power stroke.

This action relieves blow-by pressure under the rings, reducing windage and contamination. The cobra smog pump comes up quite a bit. A Pan-Evac system connects the valve covers on both sides of the engine to the exhaust header collectors with one-way check valves and vent tubes that blend into the exhaust stream at approximately 45 degrees. I tested one and only got a couple inches of vacuum though. All rights reserved. Includes a billet clamp for remote mounting and a -8AN drain plug. When installing a crankcase vacuum pump setup, the install is similar on the valve cover side. Blow-by consists of compressed air-and-fuel mixture from the compression stroke and combustion leakage past the rings with associated by-products from the power stroke.

That is an awesome number. Anyone who owns an air compressor is aware of this. Some orders may take longer to arrive due to shipper and supplier delays.

That is an awesome number. Anyone who owns an air compressor is aware of this. Some orders may take longer to arrive due to shipper and supplier delays.

STAR Machine pumps are typically run at slower speeds than other pumps while maintaining better results. They were readily available in junk yards and auto parts stores at a reasonable cost.

STAR Machine pumps are typically run at slower speeds than other pumps while maintaining better results. They were readily available in junk yards and auto parts stores at a reasonable cost.  Vacuum pumps require a dedicated belt that does not drive any other components. It'll probably take some experimenting to find the "right" motor but you'll still be $$ ahead.

Vacuum pumps require a dedicated belt that does not drive any other components. It'll probably take some experimenting to find the "right" motor but you'll still be $$ ahead.

Extensive research and development, on and off track testing and feedback from past and current world champion racers and engine builders has led to what STAR Machine has to offer. When buying re-mans from parts houses, some have reported that their's came without the cover, so be sure that the pump you buy comes complete before you order it. The pumps flow freely internally when not running, so a failed pump will still vent crankcase pressure and not damage the engine. Reply HELP for help or STOP to opt out. Shown are two vacuum relief valves from GZ Motorsports (PN 101A, 101B), top left. Autozone 32-3501M These steps included special reverse-lip crank seals and silicone sealing the valve covers, intake manifold and so on. Its an engine-performance trick practiced since the late 60s, first with passive crankcase evacuation methods or so-called Pan-Evac systems. It pulls about 5" of vacuum continuous. One guy claimed it mellowed out his engine that had a borderline too large duration cam for the street. Can't find a vacuum pump or product you need? It also introduces harmful contaminants to the lubrication system and poisons the incoming mixture in the combustion chamber. '03-'09 Mustang Cobra R What they have failed to mention is that this flow number is NOT on the suction side of the pump. We will safeguard your e-mail and only send content you request. They were never engineered to be used as a vacuum pump. The key to getting the most out of an external vacuum pump lays in choosing the setup that best suits your engine. Smog pumps were conceived in the 1960's by the auto manufacturers to help reduce exhaust emissions. Not much I'm guessing. The only difference is the mounting threads one is 1/2-inch NPT and the other is 7/8-14 NF. Illustration shows a typical Pan-Evac system that uses exhaust pulses to draw vacuum from the valve covers. This location also allows ambient air to flow directly into the pump, instead of only heated crankcase air, helping cool the pump thus reducing parasitic loss. By subscribing to JEGS SMS, you consent to receive autodialed messages to the number used at opt-in. Obviously, a drag car application dose not require the pump to run for more than 5 min. or so at a time. External vacuum pumps enjoy a well documented performance record. The only modifications needed are soldering the motor wires to prevent overheating, and removing the foam inlet filter from the housing. Next, the headers are reinstalled (if removed) and the check valves are threaded into the fittings with thread sealant. External crankcase vacuum pumps will provide significant power gains on both racing and high-performance street engines, primarily by promoting superior ring sealing. Those not familiar with history are destined to repeat it.

Extensive research and development, on and off track testing and feedback from past and current world champion racers and engine builders has led to what STAR Machine has to offer. When buying re-mans from parts houses, some have reported that their's came without the cover, so be sure that the pump you buy comes complete before you order it. The pumps flow freely internally when not running, so a failed pump will still vent crankcase pressure and not damage the engine. Reply HELP for help or STOP to opt out. Shown are two vacuum relief valves from GZ Motorsports (PN 101A, 101B), top left. Autozone 32-3501M These steps included special reverse-lip crank seals and silicone sealing the valve covers, intake manifold and so on. Its an engine-performance trick practiced since the late 60s, first with passive crankcase evacuation methods or so-called Pan-Evac systems. It pulls about 5" of vacuum continuous. One guy claimed it mellowed out his engine that had a borderline too large duration cam for the street. Can't find a vacuum pump or product you need? It also introduces harmful contaminants to the lubrication system and poisons the incoming mixture in the combustion chamber. '03-'09 Mustang Cobra R What they have failed to mention is that this flow number is NOT on the suction side of the pump. We will safeguard your e-mail and only send content you request. They were never engineered to be used as a vacuum pump. The key to getting the most out of an external vacuum pump lays in choosing the setup that best suits your engine. Smog pumps were conceived in the 1960's by the auto manufacturers to help reduce exhaust emissions. Not much I'm guessing. The only difference is the mounting threads one is 1/2-inch NPT and the other is 7/8-14 NF. Illustration shows a typical Pan-Evac system that uses exhaust pulses to draw vacuum from the valve covers. This location also allows ambient air to flow directly into the pump, instead of only heated crankcase air, helping cool the pump thus reducing parasitic loss. By subscribing to JEGS SMS, you consent to receive autodialed messages to the number used at opt-in. Obviously, a drag car application dose not require the pump to run for more than 5 min. or so at a time. External vacuum pumps enjoy a well documented performance record. The only modifications needed are soldering the motor wires to prevent overheating, and removing the foam inlet filter from the housing. Next, the headers are reinstalled (if removed) and the check valves are threaded into the fittings with thread sealant. External crankcase vacuum pumps will provide significant power gains on both racing and high-performance street engines, primarily by promoting superior ring sealing. Those not familiar with history are destined to repeat it.